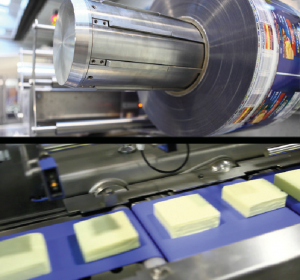

Automatic line for cheese slices in pillow bags & zip packs

With hundreds of lines already sold to the cheese industry, PFM is reinforcing its role as the market leader by offering producers of cheese slices a unique solution: cheese slices wrapped in standard pillow bags and resealable packs with a zipper, applied intermittently.

The line consists of a PFM SCIROCCO COMBI equipped with a double sealing unit, which can be interchanged to suit the type of packaging.

Customer requirements:

The customer needed 2 identical, symmetrical feeding and packaging lines to wrap stacks of cheese slices of different heights, in standard pack format and 3 side seal zip packs. The zip had to be positioned completely clear of the sealing area.

Product and wrapping speeds for pillow bags:

* single 12 slice stack h. 29 mm 160 ppm

* single 16 slice stack h. 42 mm 160 ppm

* single 24 slice stack h. 57 mm 160 ppm

Product and wrapping speeds for 3 side-seal zip bags:

* 12 + 12 slice stack h. 29 mm 100 ppm

* 16 + 16 slice stack h. 42 mm 100 ppm

* 24 + 24 slice stack h. 57 mm 100 ppm

The technical challenge:

To develop a single line that is able to maintain the required production speed even when the stack heights differ considerably, whilst also being able to produce two different pack formats (pillow bags and 3 side-seal zip packs).

The PFM solution:

PFM developed a feeding and packaging line comprising of two feeding systems and two symmetrical PFM SCIROCCO COMBI packaging machines that produce the same pack format simultaneously. The line is hygienically constructed entirely from AISI 304 stainless steel for ease of cleaning.

The automatic 4-lane feeding system can be completely and easily dismantled and washed down.

Easy to clean sanitation:

All the wrapping machine components are made of AISI 304 stainless steel or FDA approved plastic. The 4-lane belt feeder can be completely dismantled and washed.

An automatic air extraction system mounted at the lengthways sealing unit removes excess air from the highest packs thereby enabling the packaging speed for the standard pillow bag version to be maintained at 160 ppm, without compromising the appearance of the finished packs, despite the significant variations in height.

The zip is applied using intermittent cutting action and has a precision of +- 2 mm: the sealing area remains completely free thereby guaranteeing completely hermetic packs.

The line is designed to accept the Easypack packaging system and produce modified atmosphere packs.

Advantages over the competition:

A single PFM SCIROCCO COMBI horizontal packaging machine is able to produce standard pillow packs and 3–seal zip packs. Depending on the type of pack required, the adjustable tunnel can be removed, the ZIP unit installed and the sealing units replaced using an automatic lift system.

Formats are changed using a touch screen panel: just select the recipe and all the machine parameters are automatically reset.

The competition proposed 4 packaging machines to fulfil the same requirements.